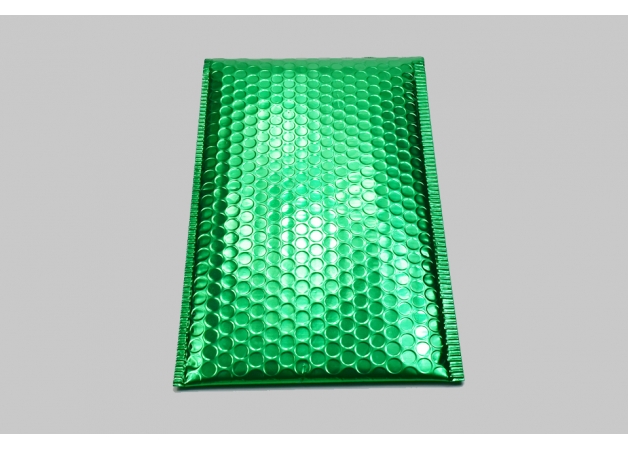

Green Bubble Mailer

Specifications / Features

Material Structure: VMPET/PE + PE bubble film

Feature:

1. Made of aluminized PET with bubble linings.

2. Superior cushioning and surface protection.

3. Self-adhesive tape available.

4. Multi-colors/dimensions available.

5. Multi-functions for mailing and packaging

6. Clean and easy to use.

7. Can be reused.

8. resistance of water, moisture, tear and shock.

9.Resistance of three types heat flow: conduction, convection and radiation.

10.Preventing inside items from damaging due to collision, attrition or static.

Application:

Packaging and transportation of high-value products, such as antiques, ceramics, jewelry, circuit boards, electrical appliances, CD, gifts, etc, moisture-proof and shockproof

Feature:

1. Made of aluminized PET with bubble linings.

2. Superior cushioning and surface protection.

3. Self-adhesive tape available.

4. Multi-colors/dimensions available.

5. Multi-functions for mailing and packaging

6. Clean and easy to use.

7. Can be reused.

8. resistance of water, moisture, tear and shock.

9.Resistance of three types heat flow: conduction, convection and radiation.

10.Preventing inside items from damaging due to collision, attrition or static.

Application:

Packaging and transportation of high-value products, such as antiques, ceramics, jewelry, circuit boards, electrical appliances, CD, gifts, etc, moisture-proof and shockproof

| Item | Unit | Test standard | Test result |

| Density (VMPET)/( LDPE) | g/cm | 1.40 / 0.92 | |

| Tensile strength: TD VMPET/ LDPE | Mpa | GB/96-04-10 | 200 / 50 |

| Tensile strength: MD VMPET/ LDPE | Mpa | GB/96-04-10 | 230 / 25 |

| Elongation rate: TD VMPET/ LDPE | % | GB/96-04-10 | 100 / 380 |

| Elongation rate: MD VMPET/ LDPE | % | GB/96-04-10 | 95 / 650 |

| Tearing strength VMPET | N/25UM | GB/T-11999 | 140 |

| Tearing strength LDPE | N/25UM | GB/T-11999 | 1000 / 90 |

| TD / MD | |||

| Dynamic friction coefficient: VMPET/ LDPE | GB/96-04-10 | 0.5 / 0.25 | |

| Moisture transmissionVMPET | RH | (G/m²,24H)40°C90%RH) | 46 |

| Moisture transmissionLDPE | RH | (G/m²,24H)40°C90%RH) | 10 |

| Oxygen Transmission VMPET | N/Cm² | N/Cm²24/1.0MPG120C90% | 120 |

| Oxygen Transmission LDPE | N/Cm² | N/Cm²4/1.0MPG120C90% | 4000 |

| Heat sel temperature | F | 170±10 | 250-375 |

| Heat seal time | Sec. | 0.3-0.5 | 0.5-3.5 |

| Heat seal pressure | P.S.I | 40-60 | 30-70 |

| Size | mm | GB/96-04-10 | Flap±5mm Length±5mm Width ±3mm |

| Appearance | GB/96-04-10 | No Delamination, Burst seal, wrinkle, wrap, break, foreign partical adherence, air bubble beyond sealling φ≤3mmΦ |

Related product

Español

Español English

English